The weather threw us a lot of

curves last weekend at Asheville. It was chilly and

cloudy, and the GUSTY winds made every landing an

adventure. My 2nd Round landing was a mis-adventure - I

ran off the end of the runway - and knocked the left

landing gear block loose from the foam wing of my Daddy

Rabbit. I

thought it might be helpful to some to see how I repaired

it. This is basically the same process that I've used to

reinforce landing gear mountings in foam wings for 20+

years.

The tools I used are pretty simple.

Here's the process.

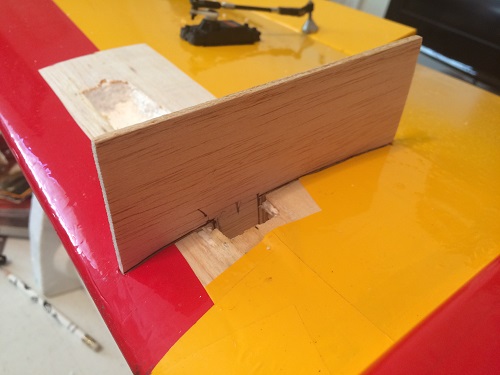

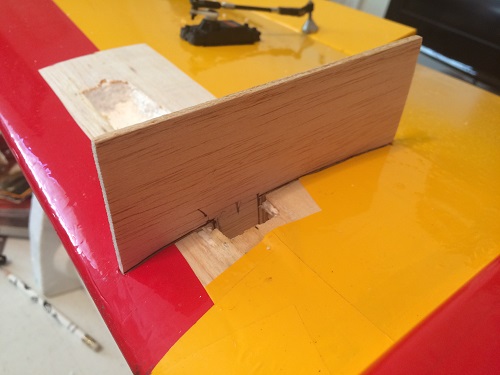

| This is the left side gear

leg with the gear block knocked loose from the foam

wing structure. It's really a lot looser than it

looks. |

|

Here's the gear block after

removal from the wing. It came out very easily.

I left the gear leg attached

to provide leverage if it is stubborn,

then got it out of the way. |

|

| Blue painters tape is used to

mark the location to cut through the bottom sheeting

and foam to the top skin of the wing to install a false

rib for reinforcement. I used my "Dremel" tool with a

large cutoff wheel to make the initial cuts. It goes

much faster that way. Final cuts were made using an Xacto knife with a long

blade. The excess foam is then dug out with whatever

is handy. I used the #1 Phillips screwdriver I had

on the bench. |

|

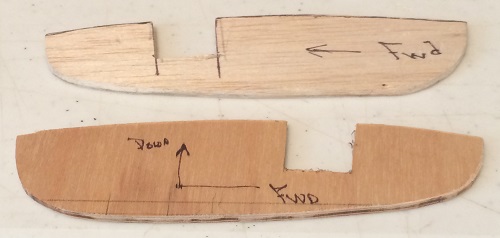

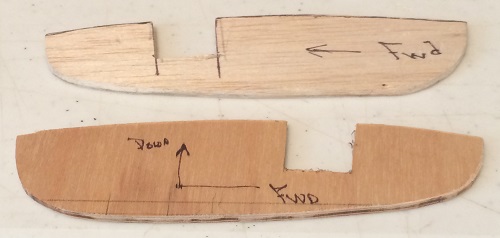

| False rib template being created from

1/8" balsa. It's cut and sanded to fit the

slot I just cut in the wing. It needs to fit snugly

against the top wing sheeting. |

|

| Here's the balsa template. |

|

A quick trip to the scrap

box produced a sheet of 1/8" 5-ply birch plywood. A

couple minutes on my trusty band saw and voila! The balsa template

(top) and the plywood false rib (bottom) cut

to rough shape.

The orientation markings are leftovers

from 26 years of working for Boeing. |

|

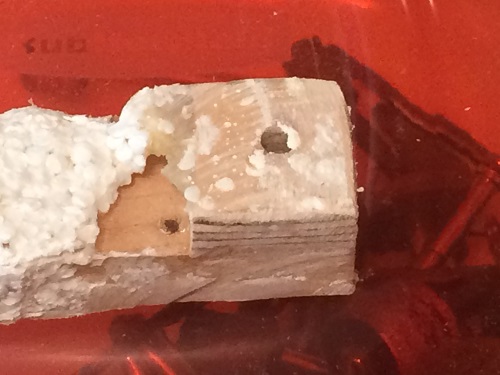

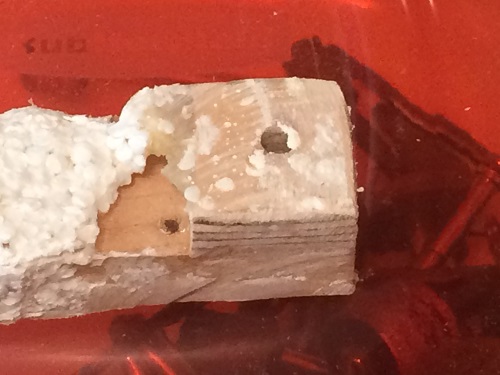

| I then ground the old

epoxy and foam from the area where the gear block

will mate with the false rib. |

|

|

Sanding the false rib to shape and fitting it to the

gear block for a nice, snug joint. |

|

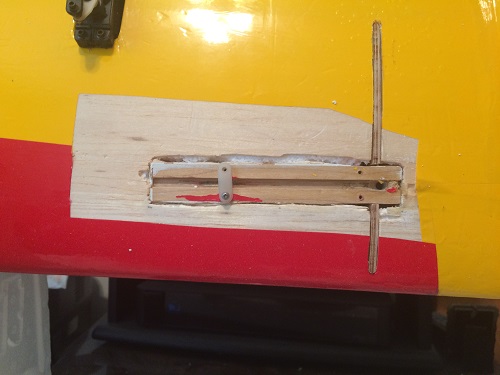

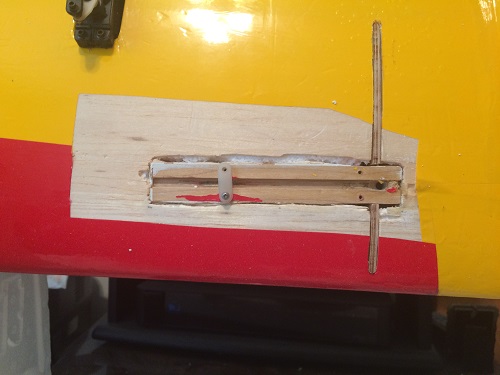

| Dry fitting the parts into

the wing to be certain everything fits. |

|

| False rib epoxied in

place. |

|

Gear block glued in with

PLENTY of epoxy. Make sure it's runny enough to

fill in ALL the little cracks and crevices in the

foam.

I'll drill out the landing gear wire hole and the

hold down screw holes to clear them of epoxy after

everything cures. The wing will be ready to recover

as soon as the epoxy cures and a little filling is

done. |

|

| Back in business and

stronger than ever. It's not perfect, but it's 100%

functional, which is good enough for me. |

|